The operating principle of the eccentric press is to change the rotary motion into linear motion – reciprocating. The electric motor drives the flywheel and at the time of the clutch, flywheel power through the crankshaft is transmitted to the slider (here turns into rotary motion into linear motion). Reciprocating slider moves, and the tool cuts or is pressed Sheet Metal.

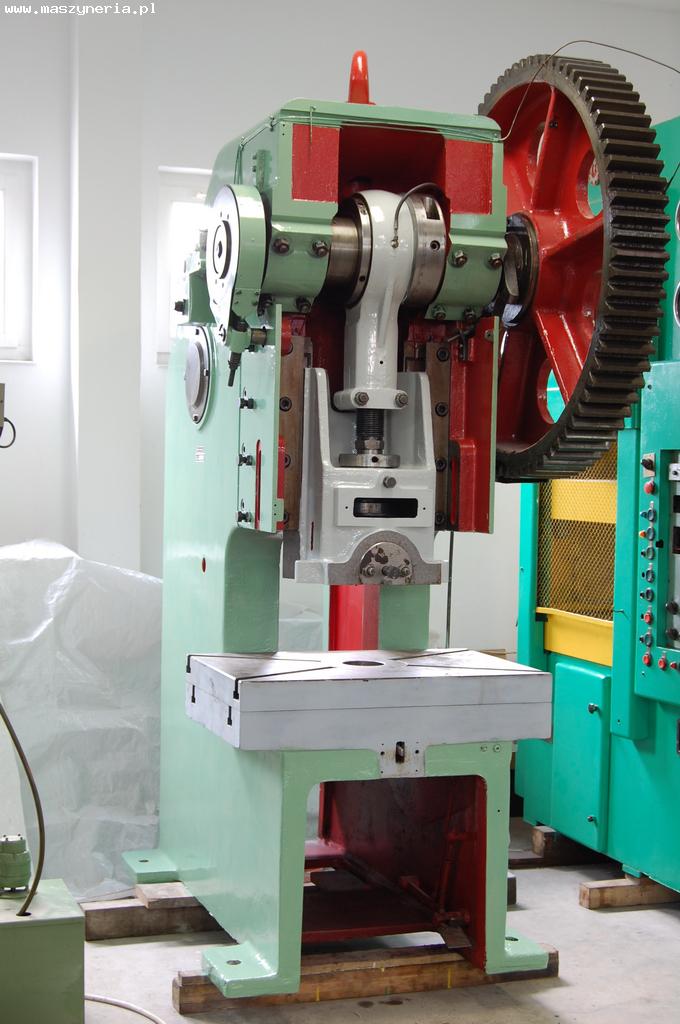

Small eccentric presses are two basic systems of the flywheel and crankshaft. The first system is a flywheel at the back of the press – the crankshaft passes from front to back. The second system is a flywheel at the side of the press – the crankshaft passes from left to right. Still, we can distinguish different types of presses: press with bottom drive (flywheel at the bottom and on the side) and press gantry (flywheels mostly inside the body).

1. Eccentric press ZTS LEK 160 – flywheel at the back of the press

Eccentric press PMS 100 – flywheel at the back of the press

2. Eccentric press LEPP 100 – flywheel on the side

Eccentric press – flywheel on the side

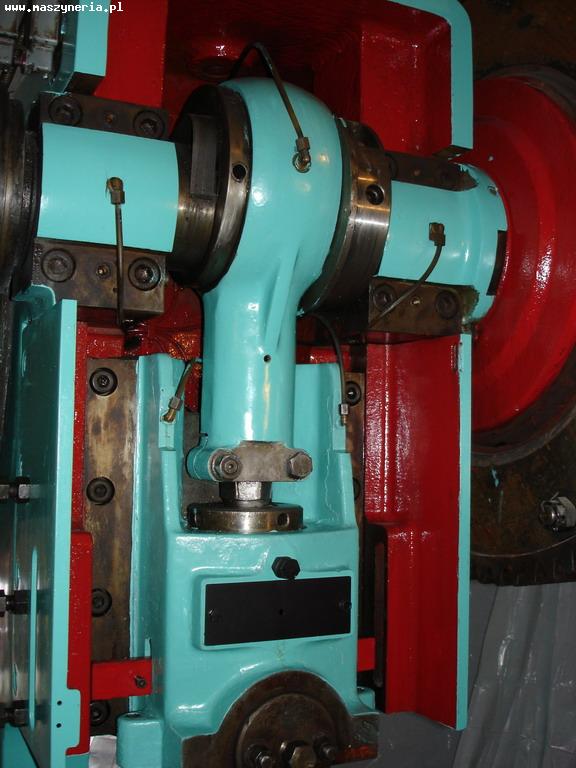

3. Eccentric press LEN P 63 – flywheel on the side

Eccentric press slider

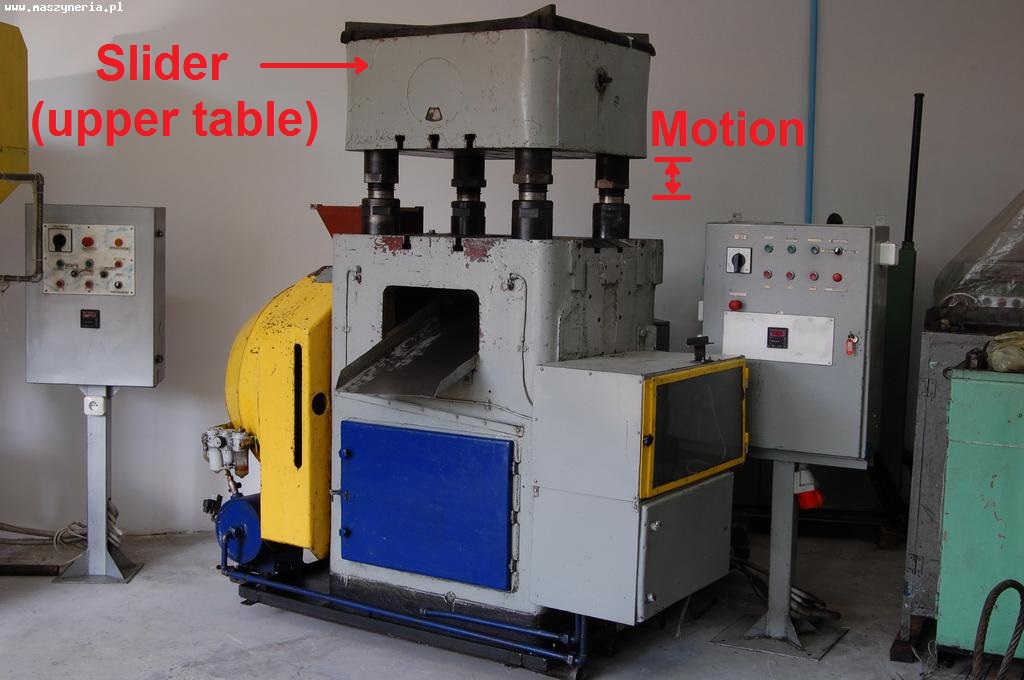

Eccentric press ERFURT PEE 400 – Slider

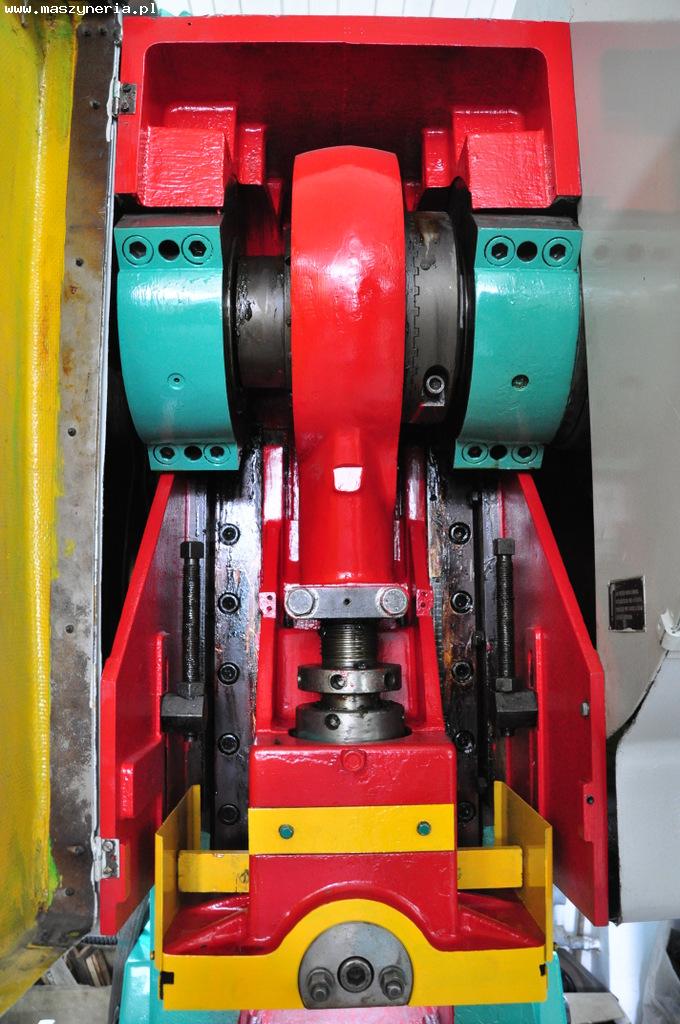

4. Eccentric press with bottom drive PAD 40