Presses are used in different industries such as light industry, metallurgy, chemical industry and other kinds of metal working industry for such operations as pressing, punching, cutting, straightening, assembly and disassembly and a lot of other operations. Mainly all presses are divided into two groups: mechanical – eccentric presess and hydraulic presses. They in turn also are divided into some groups. In this article we will talk about mechanical presses, we will consider four different presses and will decide which one is better.

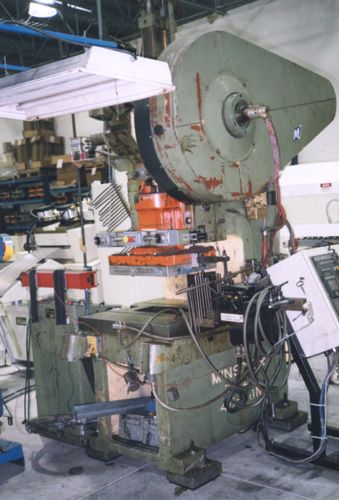

The main advantages of mechanical presses before hydraulic presses are: high speed, relatively low power drive. Our first device is eccentric press NIAGARA SA 2-150-42-36 (foto 1), which was produced in 1963 by USA manufacturer. It is the oldest among our machines. Our second machine is eccentric press MINSTER 70-4A (foto 2). It is two years younger than previous one and was manufacture in 1965 also by USA manufacturer. The third our machine is eccentric press DANLY 150 (foto 3), which was produced in 1974 also by USA manufacturer. The last our machine is H frame eccentric press SIMPAC MC 2-350 (foto 4). It is the youngest among our presses. It was manufactured just in 2010 by Korean company, which is one of the leaders in production of almost all types of presses. Let consider technical parameters of our machines. The most important characteristic of the presses is maximum pressing force. Eccentric press MINSTER 70-4A has the smallest quantity of this characteristic, which is equal only to 36.3 tons. Eccentric press NIAGARA SA 2-150-42-36 and eccentric press DANLY 150 have the same pressing force, which is bigger than in previous machine and is equal to 136.1 tons. H frame press SIMPAC MC 2-350 has the largest maximum force of the pressure, which is equal up to 350 tons. The next very important thing is measurement of the working table, which is very similar in our three eccentric presses and is much larger in our H frame press. NIAGARA SA 2-150-42-36 has length of the bottom table of 42 inches and width of it is equal to 36 inches. The length and width of the working table of MINSTER 70-4A are equal to 32 inches and 29 inches respectively. DANLY 150 has length of the working area of 34 inches and width of 24 inches. As for length and width of the table of SIMPAC MC 2-350, they are equal to 102.4 inches and 47.2 inches respectively. The last parameter, which we will consider is maximum length of the slider stroke. It is equal to 2 inches of machine NIAGARA SA 2-150-42-36. MINSTER 70-4A has maximum length of the slider stroke of 1.5 inches. Value of this parameter of press DANLY 150 is equal to 6 inches. SIMPAC MC 2-350 has the largest length of the slider stroke, which is equal up to 11.8 inches. So, in conclusion we can say that our three eccentric presses are very similar, they was produced almost at the same year by USA manufacturers, they have very similar technical parameters and have almost the same sizes and weights. They are destined mainly for details with not very large sizes, so if you need some press of this type, you can buy any of our three eccentric presses, because they are in a good condition and work very well. As for our fourth machine, H frame press SIMPAC MC 2-350, it is destined for details with large sizes and of course it has more large values of the technical parameters and also has larger measurement and weight.